IRP AMHELIE

French-Australian International Research Program in engineeringIRP AMHELIE

2020-2024

Contact:

Pr. Nicolas Saintier

nicolas.saintier(at)ensam.eu

Pr. M. Dargush

email

Pr. Aijun Huang

email

IRP AMHELIE

News

Numerical materials and 3D architectured materials

Numerical materials and 3D architectured materials

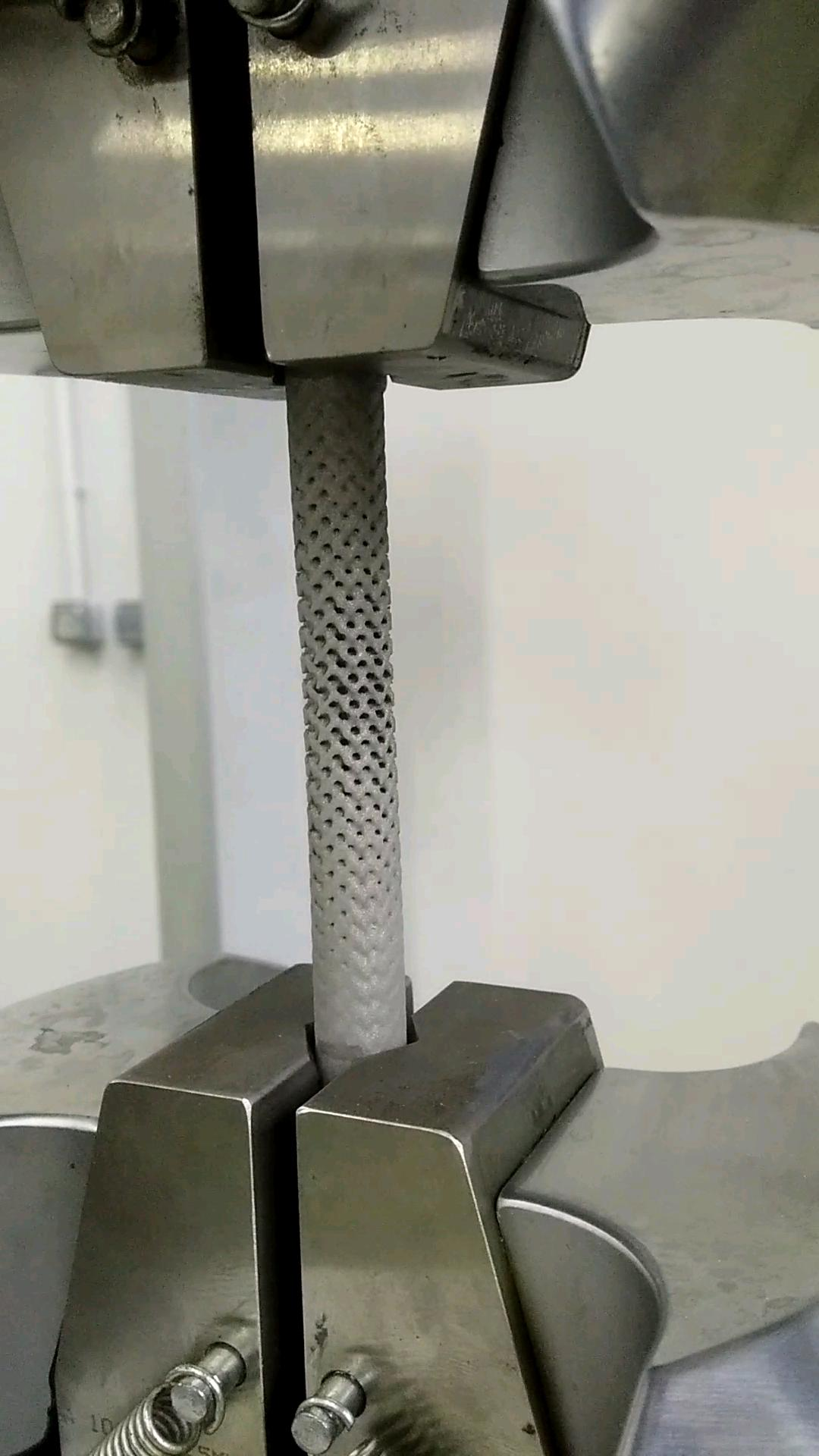

Typical lattice structures produces by ALM [1]

Introduction

The IRP AMHELIE (Additive Manufacturing for High PErformance MateriaLs and lattIce StructurEs / Additive Manufacturing for High pErformance materiaLs and lattIce StructurEs? is a project between the I2M Laboratory – UMR CNRS 5295 (Pr. N. Saintier) and the Australian universities of Queensland (Pr. M. Dargusch) and Monash (Pr Aijun Huang).

Missions and research themes

One of the major interest of additive manufacturing is the possibility of making shapes of complex geometries difficult to access by other methods. Among them, lattices structures are of major growing interest. They have the advantage, at iso local material properties, of proposing structures or micro-structures with variable density and allow to consider new engineering solutions in a wide range of applications (medical, aeronautics, space or transport sectors).

The understanding of the behavior of bulk and architectured materials obtained by additive manufacturing remains a major challenge, particularly regarding their durability and in particular their fatigue behavior with or without environmental effects. The mechanical response as well as the lifetime (under cyclic loading) at the macroscopic scale of a structure very strongly depend on its elastic-plastic behavior of the material at lower scales. Among the many parameters that drive crack initiation processes, orientation and the size of the grains (or lamella colonies in the case of titanium alloys) constitute microstructural features that play a major role in the development of micro-plasticity at small scales. These effects are all the more important as the microstructures are heterogeneous and / or the characteristic lengths of the studied structures are within the order of magnitude of that of the grains of the constitutive materials. These two characteristics are present in the case of additively obtained materials obtained by ALM and architectured materials in particular : i/ microstructure of the parts obtained by this process is strongly anisotropic and marked by the existence of internal lengths associated with the thermal history of the material (size of the laser spot, melting zone size, overlapping rate, etc …) ii/ these structures have characteristic sizes of the order the size of the grain size and thus the surface / volume effects that come into competition during fatigue damage.

MAIN projects of research

Target 1 : Developpement of new biocompatible titanium alloys (University of Queensland) and new high strength Aluminum alloys (Monash University)

Target 2 : Effect of process induced defects on the durability of materials obtained by additive manufacturing. (I2M-Monash University)

This part of the project is focused on a better understanding of natural and artificial defects on the quasi static/fatigue properties.

– process optimisation for defect control

– realisation of specimens with controled deterministic and stochastic defects

– tomography and 3D analyses of processed specimens

– experimental evaluation of the mechanical behavior materials with defects (QS/fatigue)

– multiscale numerical modeling of material with defects

– development of damage and predictability models at the structural scale including statistical analyses.

– development of damage and predictability models at the structural scale

Target 3 : Durability of architectured materials (I2M-Queensland University)

We develop experimental and numerical methodologies for the evaluation of the durability of complex architectured materials under mechanical loading (mechanical and environmental loading)

The main aspects are :

– realisation of complexe lattices geometries by FA (mostly ALM)

– tomography and 3D analyses of real geometries vs theoretical CAE

– experimental evaluation of the mechanical behavior of lattices structures

– multiscale numerical modeling of architectured materials

– development of damage and predictability models at the local scale, numerical materials

institutions and laboratories involved

France

• Pr. N. Saintier (Full Professor at Arts et Metiers Institute of Technology, Head Durability of Materials and Structures, I2M Laboratory – UMR CNRS 5295)

Australia

• Pr. M. Dargusch (Professor, Faculty of Engineering, Architecture and Information Technology. University of Queensland, Brisbane)

• Pr Aijun Huang (Professor, Platform Manager/Associate Director, Monash Centre for Additive Manufacturing. Department of Materials Science and Engineering. Monash University)

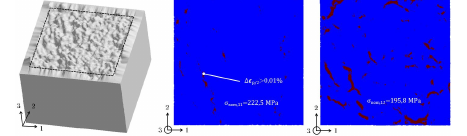

Tomography analyses and effect of etching on lattice structures produced by ALM [1]

[1] Nicolas Soro, Nicolas Saintier, Hooyar Attar, Matthew S. Dargusch,

Surface and morphological modification of selectively laser melted titanium lattices using a chemical post treatment,

Surface and Coatings Technology, Volume 393, 2020

Numerical Surface modeling for surface roughness evaluation on the fatigue behavior

[2]Bastien Vayssette, Nicolas Saintier, Charles Brugger, Mohamed El May,

Surface roughness effect of SLM and EBM Ti-6Al-4V on multiaxial high cycle fatigue,

Theoretical and Applied Fracture Mechanics, 2020.